Curious about sustainable materials? What is PLA plastic? What is PLA material? It’s a biodegradable polyester derived from plants like corn and sugarcane. Learn about its benefits, applications, and environmental impact in various industries.

What is PLA Plastic?

What is PLA Plastic? Polylactic acid (PLA), also known as polylactide, is a type of polyester derived from renewable biomass sources. Commonly, PLA is produced from fermented plant starches such as corn, cassava, sugarcane, and sugar beet pulp. This makes PLA an environmentally friendly alternative to conventional plastics, which are typically made from non-renewable petrochemical resources. Corn is often the preferred feedstock due to its low cost and widespread availability, but other sources like sugarcane and cassava are also used.

Recent advances in PLA production have focused on improving its mechanical properties and biodegradability. For example, researchers are now developing PLA blends that incorporate other biopolymers to enhance strength and flexibility, making them suitable for a wider range of applications.

What is PLA Material? How It’s Made Explained

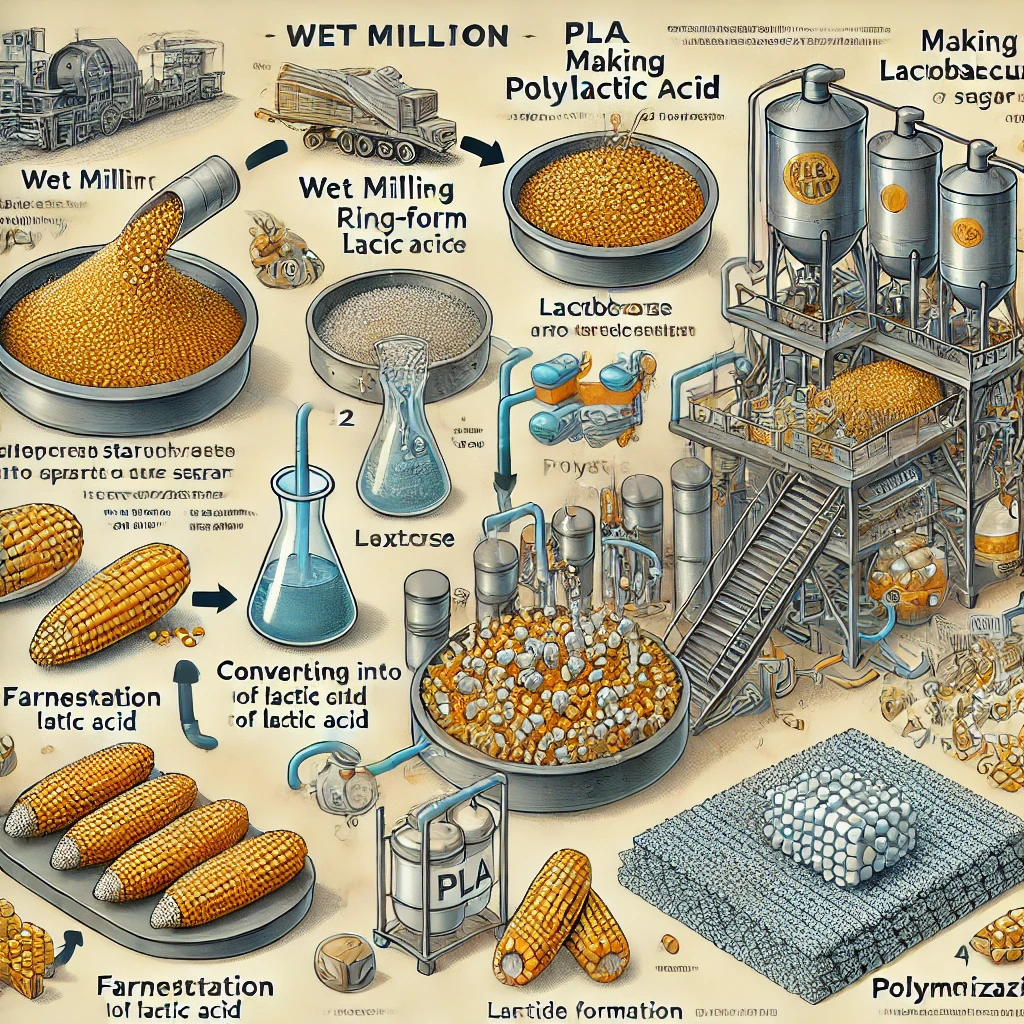

After understanding what PLA material is, let’s explore how PLA is made. The basic steps to create PLA material from corn are as follows:

Step1: Wet Milling

The process begins with converting corn starch into sugar through a mechanical method known as wet milling. This involves separating the starch from the corn kernels. Once separated, acids or enzymes are added and the mixture is heated, converting the starch into dextrose (sugar).

Step2: Fermentation

The dextrose is then subjected to fermentation. This is typically done by adding Lactobacillus bacteria to the dextrose, which ferments the sugar and produces lactic acid.

Step3: Lactide Formation

The lactic acid is subsequently transformed into lactide, which is a ring-form dimer of lactic acid. These lactide molecules bond together to form polymers.

Step4: Polymerization

The polymerization process results in small pieces of raw polylactic acid plastic. These can be further processed and molded into various PLA plastic products.

The production of PLA involves several technical steps. After wet milling, fermentation, and lactide formation, the polymerization of PLA can be fine-tuned to produce specific grades of plastic suitable for different applications.

In recent years, the PLA production process has also seen significant improvements in terms of efficiency and sustainability. Innovations such as continuous fermentation processes and the use of genetically modified bacteria have increased yields and reduced the environmental footprint of PLA manufacturing.

6 Benefits of PLA Plastic

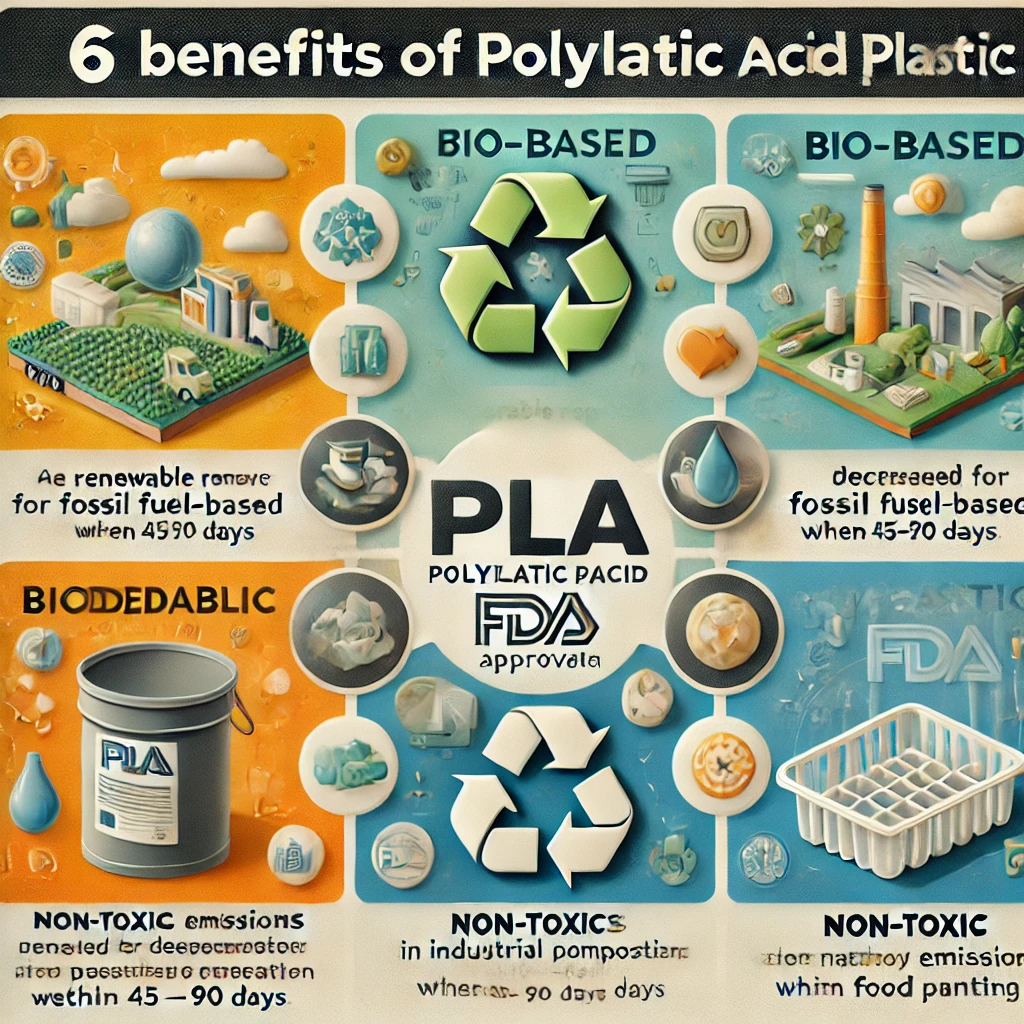

What are the benefits of PLA plastic? Polylactic acid (PLA) offers numerous benefits, making it a highly favorable alternative to traditional plastics:

1. Comparable to PET Plastics:

PLA products are a functional and renewable replacement for conventional plastics, over 95% of which are derived from finite natural gas or crude oil resources. These fossil fuel-based plastics are not only hazardous but also limited in supply.

2. Bio-based:

PLA products are derived from renewable agricultural sources or plants, primarily from sugar starches, making polylactic acid a bio-based material.

3. Biodegradable:

PLA plastic meets international standards for biodegradation, meaning it naturally decomposes rather than accumulating in landfills. According to research published in the journal “Polymer Degradation and Stability”, under specific conditions, such as in an industrial composting facility, PLA can break down within 45–90 days. This biodegradability is a significant benefit of PLA plastic.

4. Non-toxic Emissions:

Unlike traditional plastics, PLA bioplastics do not emit toxic fumes when incinerated, making them safer for the environment.

5. Thermoplastic Properties:

As a thermoplastic, PLA material becomes moldable and malleable when heated to its melting temperature. This allows it to be solidified and injection-molded into various forms, making it ideal for applications like food packaging and 3D printing.

6. FDA-approved:

Polylactic acid is recognized by the FDA as a Generally Recognized as Safe (GRAS) polymer, ensuring its safety for food contact. This approval underscores the safety benefits of PLA plastic.

Is Polylactic Acid Biodegradable?

Polylactic acid (PLA) is indeed biodegradable, making it an environmentally friendly alternative to traditional plastics. Is polylactic acid biodegradable? Yes, PLA meets international standards for biodegradation, meaning it naturally breaks down over time rather than contributing to long-term landfill waste.

However, it’s important to note that PLA material requires specific conditions to degrade efficiently. In an industrial composting facility, where the environment is carefully controlled with high temperatures and adequate moisture, PLA can decompose within 45 to 90 days. This controlled composting process ensures that PLA products can return to the earth without leaving a lasting environmental footprint.

Recent studies have shown that advancements in composting technology are further reducing the time required for PLA to break down, making it an even more attractive option for waste management. Researchers are also exploring the use of enzymes and other biological catalysts to enhance the biodegradation process of PLA in natural environments.

Read more: Is Polylactic Acid Biodegradable? Uncovering the Facts About PLA

Is PLA Plastic Food Safe?

Yes, PLA plastic is considered safe for food contact. The question, “Is PLA plastic food safe?” is answered by the U.S. Food and Drug Administration (FDA), which has approved polylactic acid as a Generally Recognized as Safe (GRAS) polymer. This certification means that PLA meets stringent safety standards and is deemed safe for use in food packaging and other food-related applications.

PLA’s non-toxic nature further enhances its suitability for food contact, as it does not emit harmful fumes when incinerated. Its thermoplastic properties allow it to be molded into various forms, making it an excellent choice for items such as food containers, utensils, and packaging.

Continue reading:Is PLA Plastic Food Safe? Exploring the Safety and Risks of PLA!

6 Common Polylactic Acid Uses

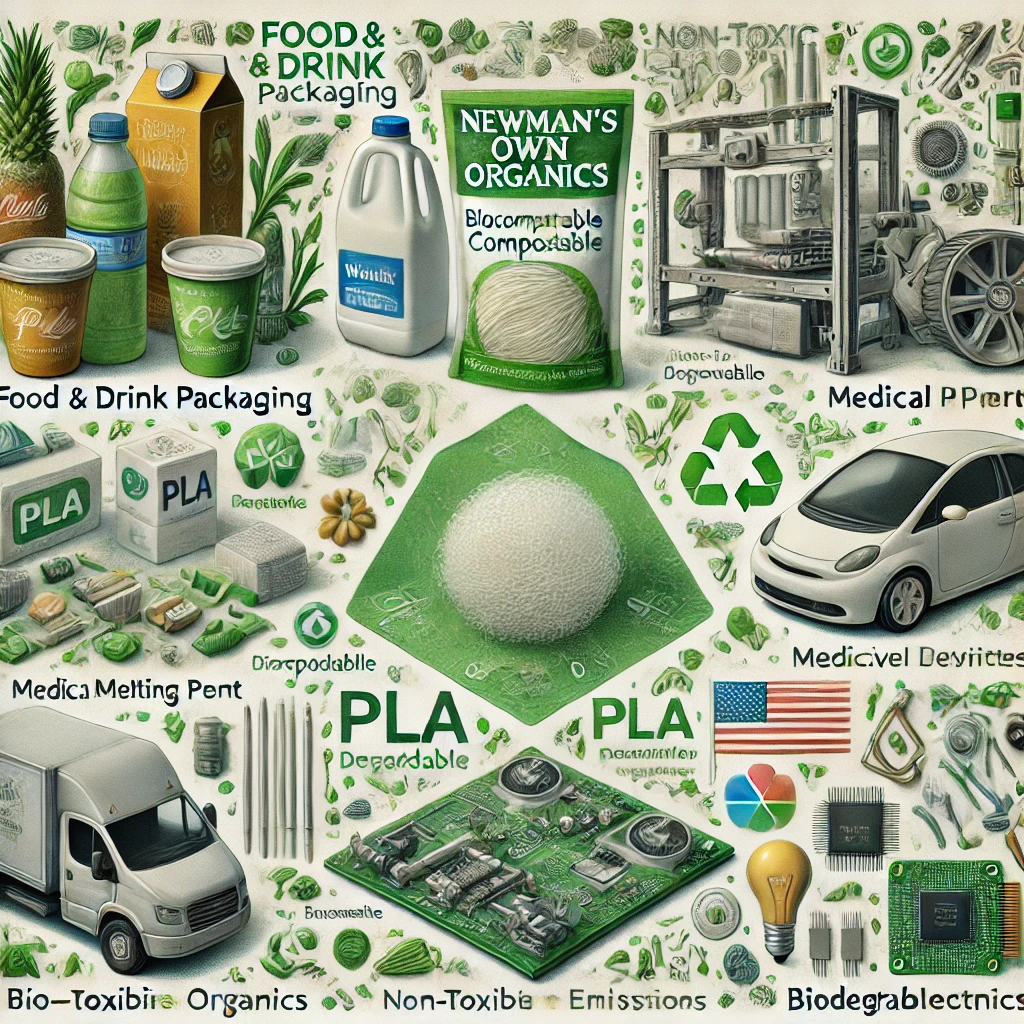

Polylactic acid (PLA) plastic is widely used across various industries due to its environmental benefits and versatility. Here are some of the key applications:

1. Food and Drink Packaging

PLA plastic is extensively used in food and drink packaging. Companies like Walmart, Newman’s Own Organics, and Wild Oats use compostable PLA packaging for its safety and sustainability. PLA packaging is biocompatible and does not leach harmful chemicals into food, and it breaks down in industrial composting facilities, reducing landfill waste.

2. 3D Printing PLA Filament

PLA filaments are a popular choice for 3D printing because of their lower melting point and non-toxic emissions. They provide a safer printing environment compared to other filament options.

3. Medical Implants and Devices

PLA material is favored in the medical field for its biocompatibility and safe degradation into lactic acid. It is commonly used in drug delivery systems, medical implants, and tissue engineering.

4. Fibers and Textiles

In the textile industry, PLA fibers are used to replace nonrenewable polyesters. PLA fabrics are lightweight, breathable, and recyclable, making them a sustainable alternative.

5. Automotive Parts

The automotive industry is exploring PLA for lightweight and biodegradable car parts. PLA composites are being used for interior components, reducing vehicle weight and improving fuel efficiency.

6. Electronics

PLA material is being used in electronics for biodegradable circuit boards. This innovation aims to reduce electronic waste and enhance the sustainability of electronic devices.

Read more: Polylactic Acid Uses and Benefits You Need to Know!

Sustainable Solutions: PLA Food Packaging

Polylactic plastic is a sustainable, versatile, and biodegradable alternative to traditional plastics, ideal for food packaging and more. Derived from renewable resources like corn and sugarcane, PLA material is used in food containers, utensils, 3D printing, medical implants, and textiles. Its non-toxic emissions and FDA approval for food safety make it an ideal choice for various applications.

If your business uses items such as takeaway food containers, straws, or compostable plastic bags and you are passionate about sustainability and reducing your carbon footprint, PLA packaging is an excellent option. To explore more about PLA products and their benefits, visit ONENICE for detailed information and product options.

Recommended articles:

How to Organize Bathroom Toiletries for a Clutter-Free Haven!

Wall Storage for Small Bathroom: 9 Steps to Maximize Space!